Part design and analysis have been a "black art" since Compression Molding's inception many years ago, where experience, manufacturing processes, and numerous trade secrets have been developed and perfected to make molded parts manufacturing an extremely popular Efficient and efficient way of manufacturing a variety of plastic products.

The original notion of molding was used in the baking business to make cookies and cakes before advanced plastics were ever molded. However, since 1907, when Leo Baekeland used a crude compression machine, formaldehyde resin, and steam to manufacture the first plastic molds, compression molding continued to grow and expand to become an important manufacturing process. You can also navigate to this website to buy a compression molding machine.

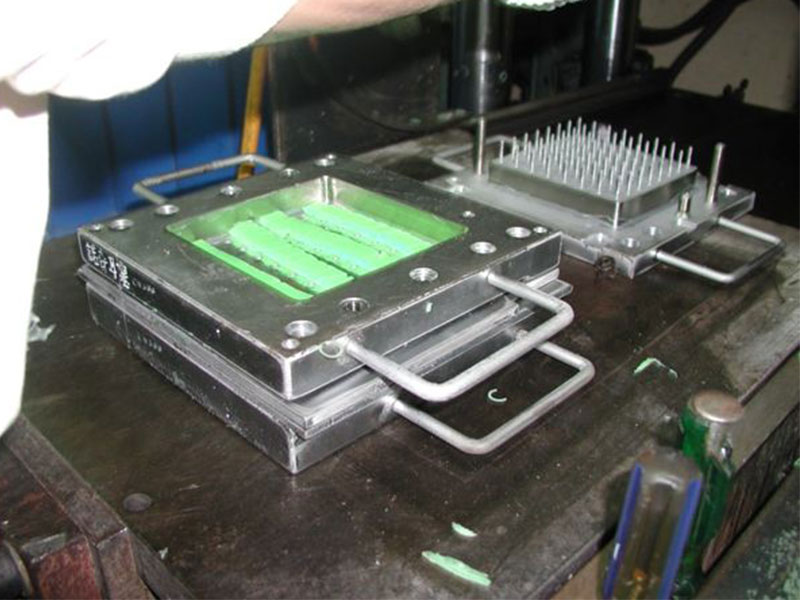

Image Source: Google

Advantages of Compression Molding

The advantages of the technology are obvious, and they far outweigh some of its drawbacks. Manufacturing processes are still used today in industries around the world to produce parts, components, and complete products for a variety of reasons.

fast set up a time

low initial setup cost

Capable of sizing parts beyond what is possible with most extrusion techniques

Allows casting of large and small complex parts

Capable of good surface finish

wastes little material

One can take advantage of thermoplastics with unidirectional tapes, woven fabrics, fiber mats, and more.

This method of molding results in fewer weave lines and less fiber-length degradation than other processes such as injection molding.